Controlling the temperature and air composition is what it’s all about during the storage period of living products. Potatoes in particular keep ‘breathing’ during storage, consequently converting oxygen in, among others, CO2. Keeping the CO2 level under 5000 ppm is most beneficial to the quality of the potato.

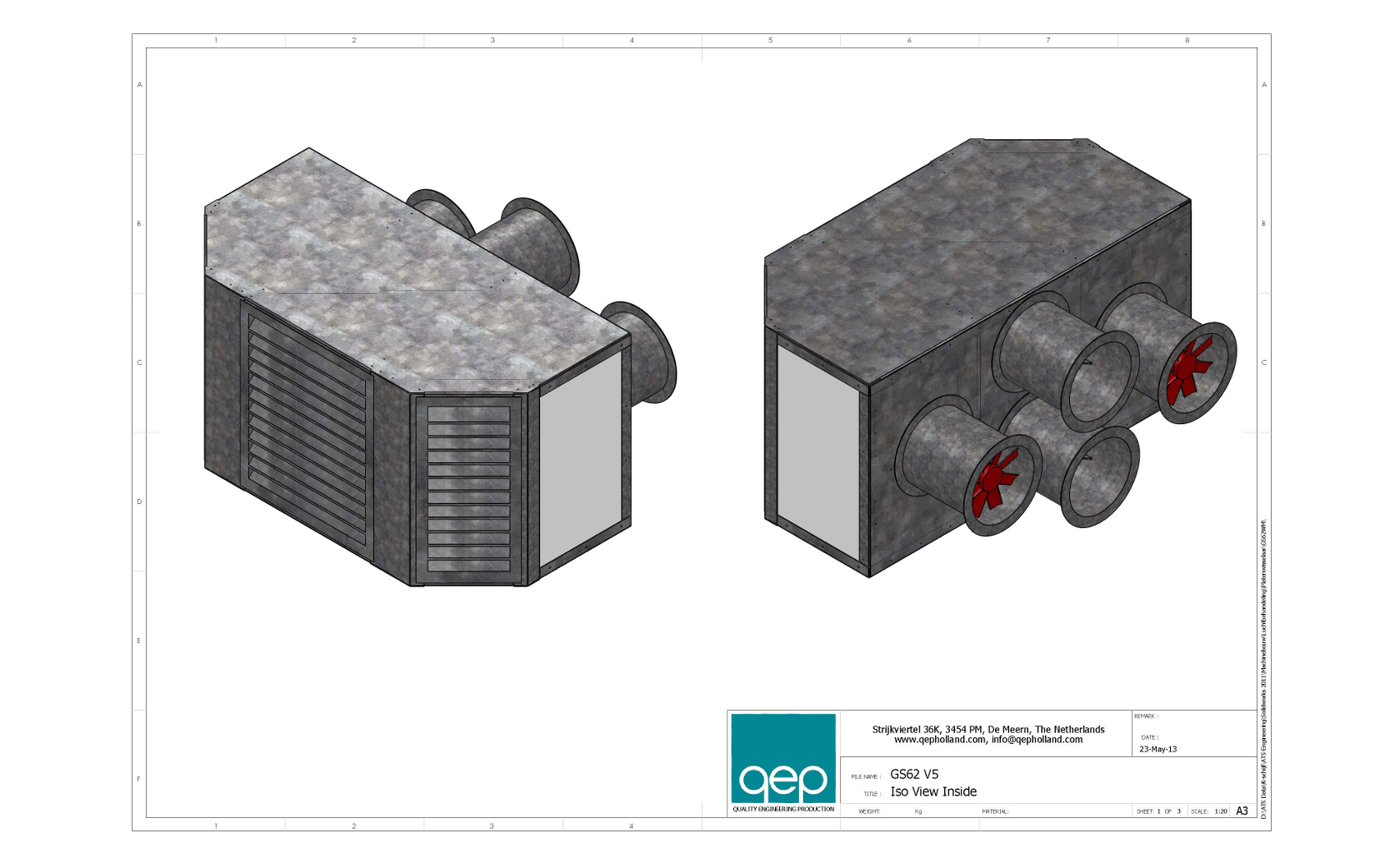

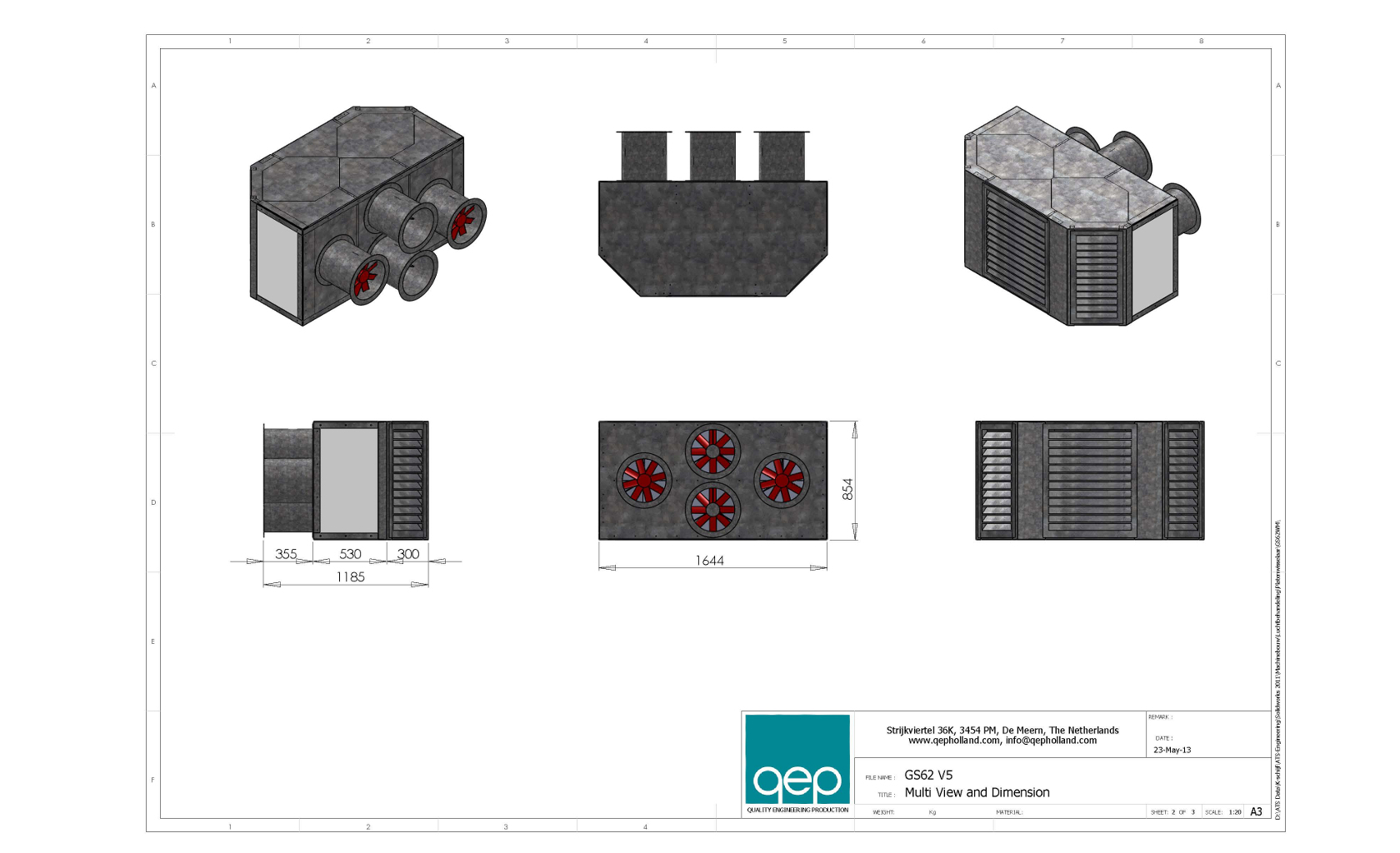

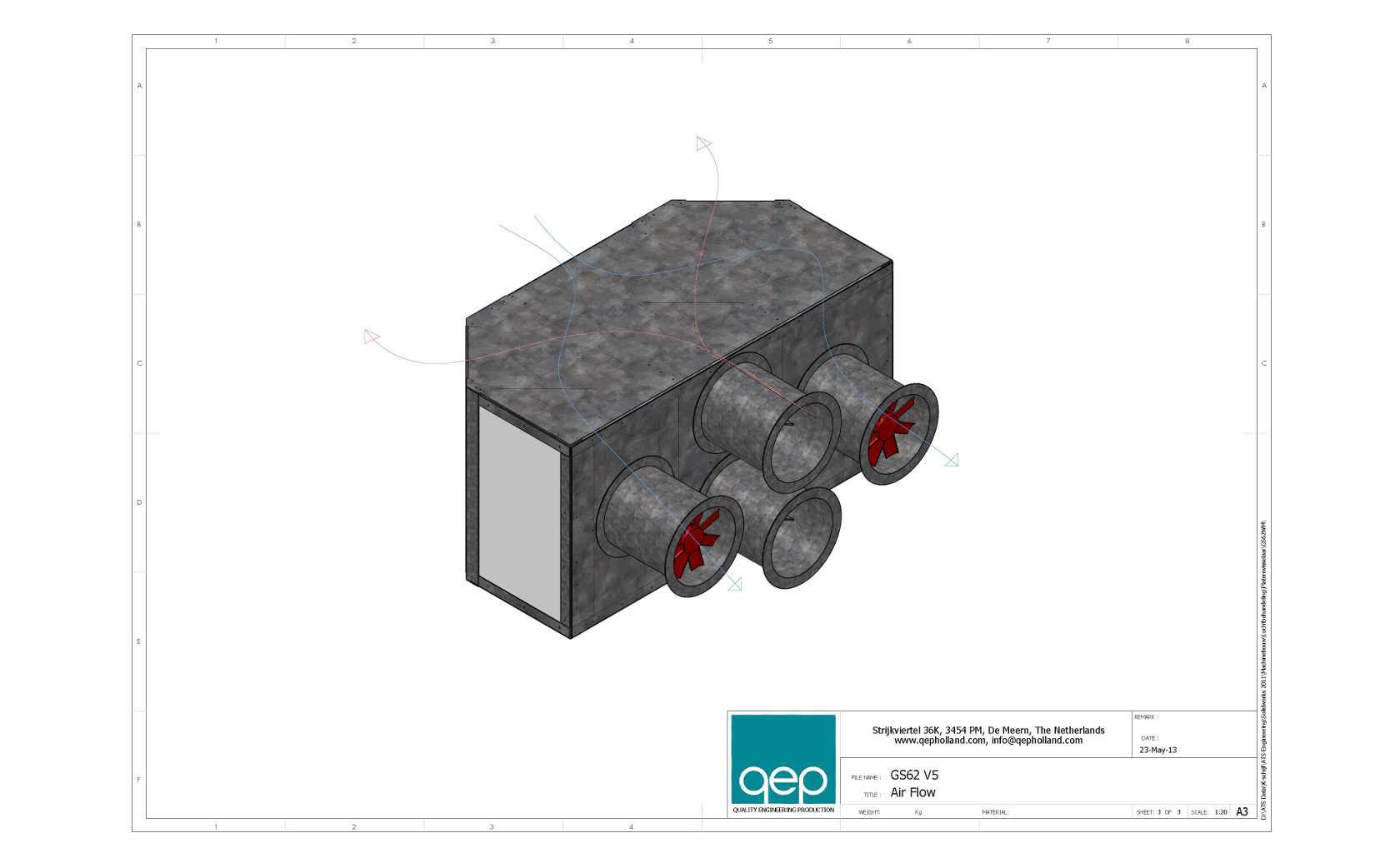

The CO2 level can be controlled using outside air ventilation, given the conditions are favourable. In other circumstances, e.g. a tropical climate or a hot springtime, the CO2 level must be reduced in another way. In those cases the QEP HE-A heat exchanger unit for air can be a solution. Outside air is channelled through the heat exchanger into the storage, while the inside air is funnelled out in a cross flow.

Warm outside air is cooled by the inside cold air, realising a big energy saving. Efficiency can reach up to 95%, where the outside air reaches virtually the same temperature as the inside air. An approximate 4000 m³/hour air displacement allows for a swift CO2 level reduction.

The QEP HE-A is both used for bulk storage and box storage and can simply be placed on the pressure wall or through the exterior wall. Fan regulation is made possible with the supplied control panel. Optimal efficiency is reached by combining the heat exchanger unit with the turn key cooler.

Advantages

- High efficiency

- Straightforward installation

- Low energy consumption

- Light and compact construction

Characteristics

- Modular build

- Low maintenance

- Produced with corrosion resistant aluminium

- Including drip tray for draining moisture

Options

- Exterior wall or pressure wall mounting

- Frequency controlled fans

- Connectable with existing ductwork